Drag Chain Conveyor Manufacturer and Supplier in UAE and Middle East Regions.

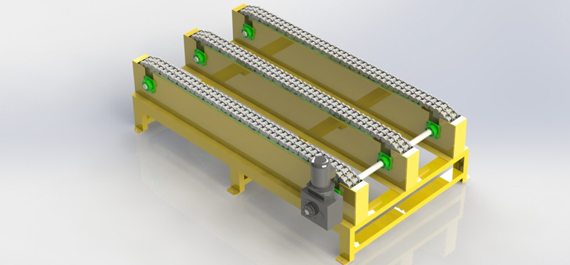

When moving large or heavy objects over great distances, a drag chain conveyor is an effective and popular choice among industrial and manufacturing facilities. Metal or another material is wound into a chain that travels along a track, usually with a number of linked, overlapping flights or paddles. Materials that are too heavy, too big, or otherwise difficult to transmit with other kinds of conveyors can be effortlessly moved by drag chain conveyors.

Because of its effectiveness and capacity to handle dry, free-flowing materials, drag chain conveyors are particularly useful in the railroad, cement, chemical, and agricultural industries, among others.

For the conveyance of bulk materials, conveyors are a popular option. Belts, chains, augers, buckets, and other mechanical devices are used to move material from the input to the output. Conveyor systems made of drag chain are yet another well-known brand.

Go no farther than PressureTech if you require a drag chain conveyor in the United Arab Emirates. It can move comparable materials on both level and sloped surfaces, including clinker, cement, sinter dust, uncooked meal, and others. The size of the things being moved is important because these conveyors aren’t made to move large or heavy objects.

Drag conveyors are built by subject-matter experts in accordance with recognized industry standards; their modular design makes them suitable for a wide range of applications.

Pressure Tech is now widely recognized as a leading manufacturer of drag chain conveyors in the UAE. All conveyors will be sent to the following UAE locations: Ajman, Ras Al Khaima, Abu Dhabi, Sharjah, and Dubai.

Drag Chain Conveyor Features:

Drag Chain Conveyor Applications: