Slat Conveyor Manufacturer and Supplier from UAE and Middle East Regions.

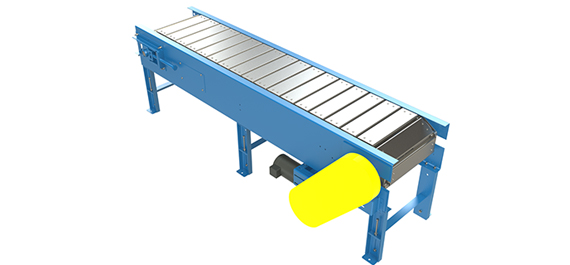

A slat conveyor is a type of conveyor system used in various industries for transporting heavy or irregularly shaped objects or materials within a production or manufacturing environment. It is characterized by a flat, rigid platform composed of individual slats or plates that are linked together to form a continuous moving surface. Slat conveyors are particularly well-suited for handling items that might not easily move on other conveyor types, such as pallets, large cartons, or heavy industrial components.

Chain attachments are used to connect steel plates to the chain. An electric motor and gearbox power the chain. Because of this, they are one of the most popular types of conveyor used to move parts along an assembly line while the work is being done. These are perfect for situations where parts need to be put together on a mount that is at a good working height.

In a car plant, parts like instrument panels, center dashboards, and door trims may be moved with a slat rail system. They’re used to put the engine and transmission together. They are also used to put together parts of frames and wheels. Bigger ones are used for cars after the frame parts are put on and the cars move to the final assembly line, which is sometimes called a “flat top” conveyor line. Due to the way the slats look and work, some customers call them “slat conveyor belts.”

Pressure Tech is the leading slat conveyor manufacturer and supplier in UAE. We ship conveyors all across the United Arab Emirates, including to Dubai, Sharjah, Abu Dhabi, Ras Al Khaimah, and Ajman.

Slat Conveyor Features

Slat Conveyor Applications:

Industry:

Slat Conveyor Benefits:

- Great for putting together products on a moving assembly line or while the line is stopped at each work station (before moving to the next spot). They make a great safe place to work.

- Slat conveyor systems work well when most of the parts can be reached from above. If you need access from both sides, you might want to use an overhead hoist with a fixture that can turn.

- Use these conveyors to move goods along the line that need to stay in place.

Fixtures shouldn’t stand up too high. Remember that the fixture will be attached to the panels and will go back under the conveyor to the starting place. This means that you will need space on the floor for the return path of the tooling and fixture. If the clearance is tight, the conveyor can be raised 10 to 24 inches off the floor and a compensating work platform can be added along the working side of the conveyor to keep the workers in a good ergonomic position. - Industrial slat conveyors can move in either a continuous or an indexing mode. In an indexing mode, a sensor tells the slat conveyor when to stop and start moving a product to the end of the line.

- As the fixture is always in the same place, it works very well for automatic loading and unloading. With the right safety measures, both humans and robots can do assembly work on the same assembly line.

- Work well when the speed needs to be changed. When they have a VFD (variable frequency drive), it’s easy to change the speed on them.